Services

Our Services

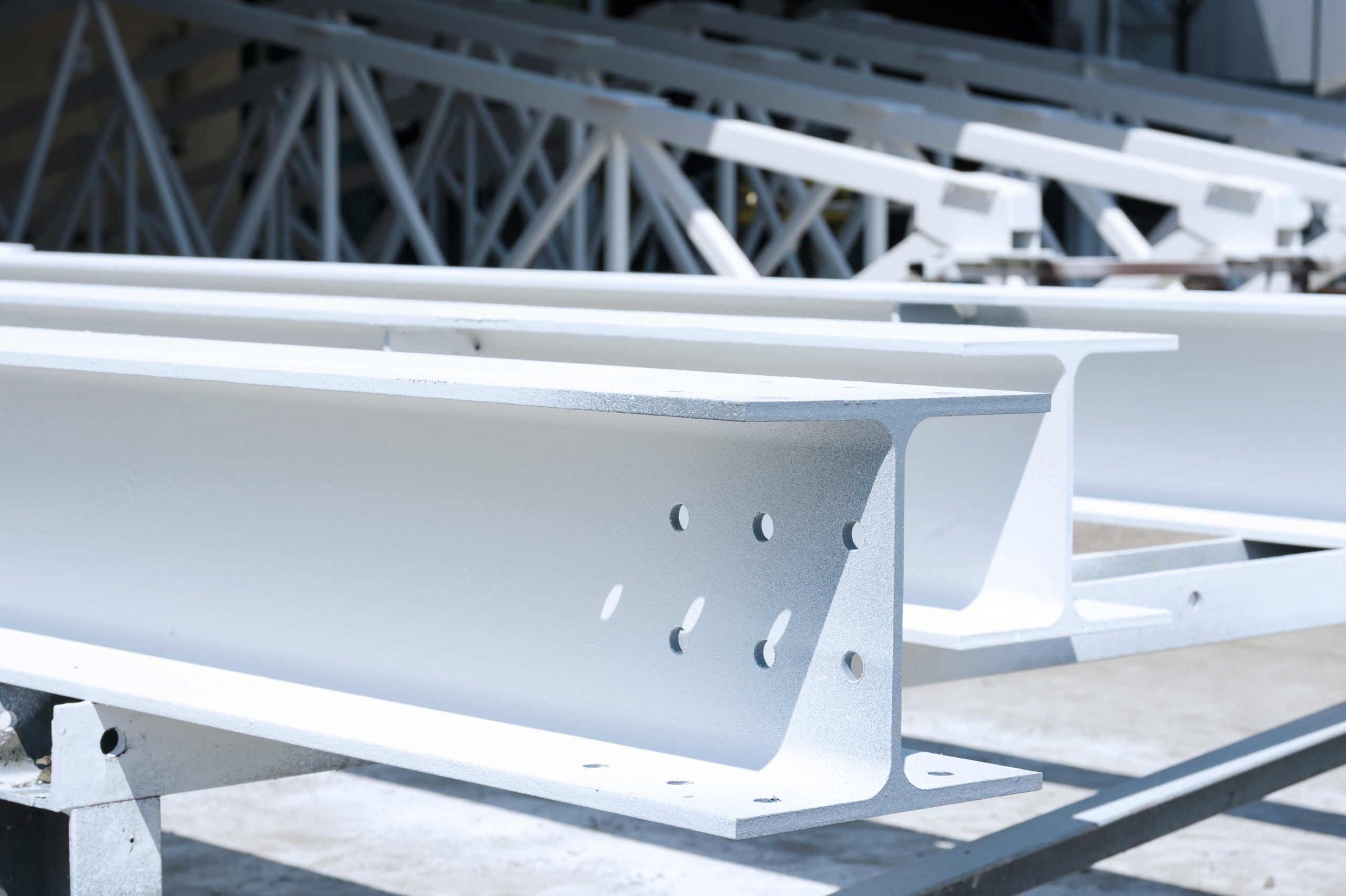

We Provide the best services in the industry. Our goal is to find a solution to allow visions of our Clients to materialise regardless of specifications or budget. Our services include:

01.

Painting

Paint is commonly used to protect steel and increase its life.

02.

Galvanizing

Galvanizing protects architectures against corrosion and make them resistant to weather.

03.

Blasting

Blasting is a method used to clean the steel surface and make it suitable for subsequent painting or galvanizing.

Our Specialization

We specialize in hot dip galvanizing for mild steel structures and pipes. Our main services include:

Painting

Paint is commonly used to protect steel. Modern specifications usually comprise a sequential coating application of paints. Sometimes, due to aesthetics requirements, steel articles are also painted after galvanizing which is called duplex system. A normal painting system will usually consist of primer coat, intermediate coat and finish coat.

- Call Us Today

+971 2 556 5514

Galvanizing

Galvanization is the process of applying a protective coating layer to steel articles to prevent their rusting. Zinc protective coating protects the substrate steel in following ways

- The zinc layer on steel protects air & moisture to reach steel surface. In absence of air & oxygen steel can’t be oxidized. Zinc layer itself will oxidize very slowly as compared to paint and will give a life of 10-50 years depending upon the environment, in which galvanized articles are installed.

- Even if, zinc coating is scratched or underlying steel is exposed to air, zinc will corrode first and will act as cathode. Corrosion protection can continue as long as there is zinc close enough to be electrically coupled. After all of the zinc in the immediate area is consumed, localized corrosion of the base metal can occur. This phenomenon is called cathodic protection.

Blasting

Blasting is a method used to clean the steel surface and make it suitable for subsequent painting or galvanizing. Blasting can be done by grits, sand, steel shots & garnet & different surface profiles can be achieved by changing the blast media, changing the blasting technique & other operational parameters. Shot blasting is best & most economical option to prepare steel articles for galvanizing.